Special multifunction machine for machining carbide parts

Project 3250

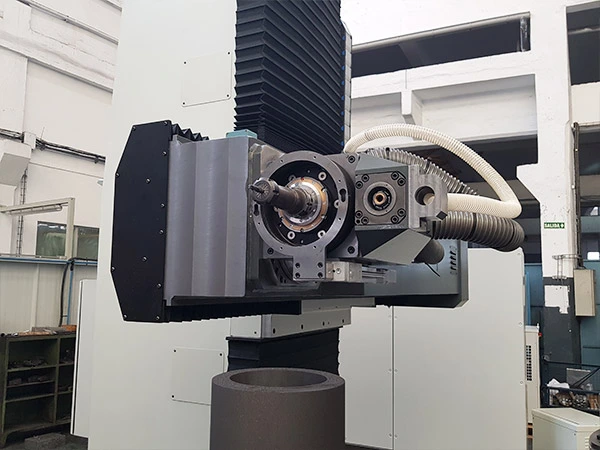

Custom-developed machine tool designed for machining carbide and other low-hardness materials, requiring a combination of milling and turning operations on a single piece of equipment.

This special machine features 4 continuous motion axes (X, Y, Z, C) and an automatically positionable A axis, enabling flexible operation in both rotary machining (lathe mode) and milling.

In turning mode, the chuck rotates as the C axis; in milling mode, the machine uses a positionable electrospindle (A axis) that allows switching between milling and turning tools using a single head.

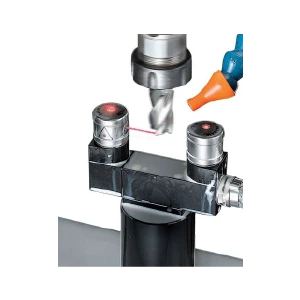

The project also integrates several auxiliary systems that enhance productivity and ensure quality control: an automatic tool changer, a dust extraction system for machining processes, and a measurement system for both milling and turning tools.

Product 3250 – Customised special machines

Technical characteristics

| Max. workpiece Ø | 900 mm |

| Ø plate | Ø plate 1000 mm |

| Max. weight. | 1800 kg |

| Max. coil RPM | 300 rpm |

| Turning power | 37 kW |

| “X” axis travel | 1010 mm |

| “Y” axis travel | 825 mm |

| “Z” axis travel | 2000 mm |

| Axis ‘A’ spindle travel | +60º / -90º |

| Milling power | 30 kW |

| “X” axis speed | 24 m/min. |

| “Y”axis speed | 24 m/min. |

| “Z” axis speed | 24 m/min. |

Accessories

Head HSD-ES505

Measuring tool

Tool storage

Number of tools: 12 tools.

Types of tools: HSK-A63