Special milling machine for machining high-hardness railway components ferrocarril

Project 1221

Gantry milling machine developed as a customized solution for a railway sector client, specifically designed for machining large-format parts used in tracks and turnouts.

This machine primarily works with manganese steel, a high-hardness material commonly used in these types of applications.

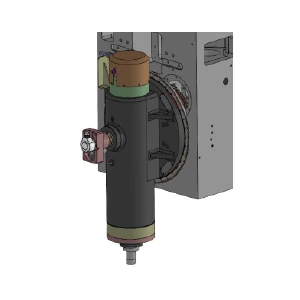

It features a configuration with 3 continuous motion axes (X, Y, Z) and an automatically positionable A axis, enabling machining on both flat and inclined planes. Additionally, it is equipped with a dual-pallet table system that allows tandem operation, optimizing loading and unloading times and increasing productivity in repetitive tasks.

It also includes an automatic tool changer and a chip collection system, ensuring process efficiency and continuous cleanliness during machining.

Product 1221 – Custom-made special machines

Technical characteristics

| Distance between columns | 1800 mm |

| Longitudinal route | 13000 mm |

| Transversal route | 1800 mm |

| Vertical travel | 400 mm |

| Axis ‘A’ spindle travel | ± 95° |

| Longitudinal speed | 10 m/min. |

| Transverse speed | 6 m/min. |

| Vertical speed | 6 m/min. |

| Milling power | 55 kW |

| Milling speed cab. ppal. | 840 rpm |

| Milling speed cab. aux. | 1500 rpm |

Accessories

CMI auxiliary head (x1)