RETROFITTING

Service

At CMI Durango, we offer an industrial retrofitting service designed to upgrade large, legacy machinery and restore its full potential. We modernize both mechanical and electrical/electronic systems, incorporating current technology that enhances equipment precision, safety, and performance. All with a significantly lower investment than purchasing a new machine.

OUR SERVICE

What does our retrofitting service include?

We carry out a complete machine upgrade, including:

- Renovation of electrical and electronic systems.

- Integration of new CNC controls and drives.

- Replacement of kinematic components (spindles, racks, gears, etc.)

- Elimination of unnecessary transmissions.

- Installation of electronic measurement systems

- Updated lubrication system.

- Aesthetic renovation: new enclosures and safety guards.

- On-site commissioning and operator training.

Our technical team analyzes each case in detail and designs the most suitable solution based on the machine’s condition and characteristics.

What are the advantages of industrial retrofitting?

Significant cost savings compared to purchasing new machinery.

Improved productivity and machining accuracy.

Enhanced safety and regulatory compliance.

Adaptation to current control systems.

Customization based on your actual production needs.

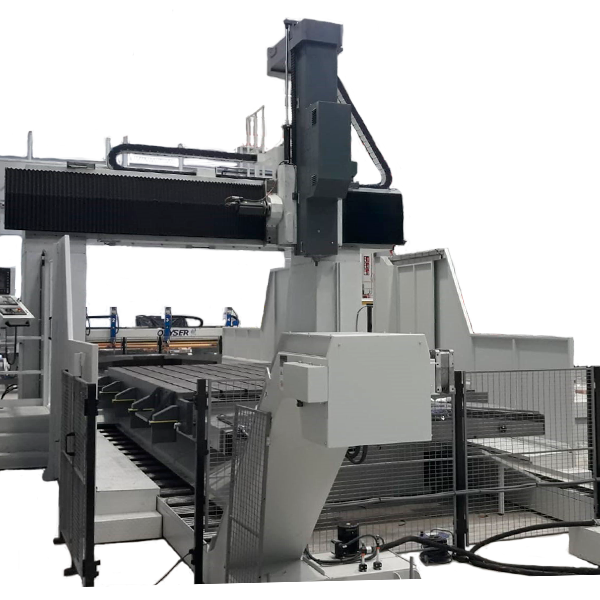

Industrial machinery retrofitting

How do we handle retrofitting at CMI Durango?

In most cases, the customer provides the base structure of the machine. From there, our team evaluates, redesigns, and implements all necessary upgrades, delivering a fully renovated, functional machine adapted to your production environment.

What types of machines is this service for?

This retrofitting service is especially suited for large-format machines, vertical lathes, heavy milling machines, and other complex industrial equipment whose structure remains valid, but whose control systems and mechanical components require an update.