Choosing a vertical lathe is much more than deciding which machine to buy. It is a strategic investment that must be aligned with your processes, technical requirements, and productivity objectives.

In an increasingly demanding and specialized industrial environment, a standard solution is not always enough. At CMI Durango, we know this well. With more than 80 years of experience designing and manufacturing machine-tool solutions, we develop equipment tailored to specific production environments and real industrial needs. We do not believe in universal machines. We focus on customized solutions designed to respond precisely to what each plant requires.

En este artículo, repasamos los factores clave a tener en cuenta a la hora de elegir un torno vertical, y te explicamos cómo nuestras gamas RERIS y QUALITAS ofrecen respuestas técnicas a diferentes tipos de requerimientos industriales.

Which factors should you consider?

Before deciding which vertical lathe you need, there are five key aspects to analyze:

1. Type of part and machining complexity

Do you work with large, heavy components? Do you need multiple operations such as milling, drilling, or tapping? These variables determine the most suitable machine configuration.

2. Precision requirements and production volume

Machine stability, repeatability, and tolerance levels must match your production pace and quality requirements, whether for small batches or long production runs.

3. Plant layout and available space

Available floor space can define machine size and layout. Design flexibility is essential in facilities with physical constraints.

4. Level of automation

Do you need automation systems, measuring devices, or integration with plant software? The machine must support the required level of digitalization.

5. Maintenance strategy and expected service life

Reliability and preventive maintenance directly affect medium- and long-term profitability.

Our solutions: vertical lathes designed with technical criteria

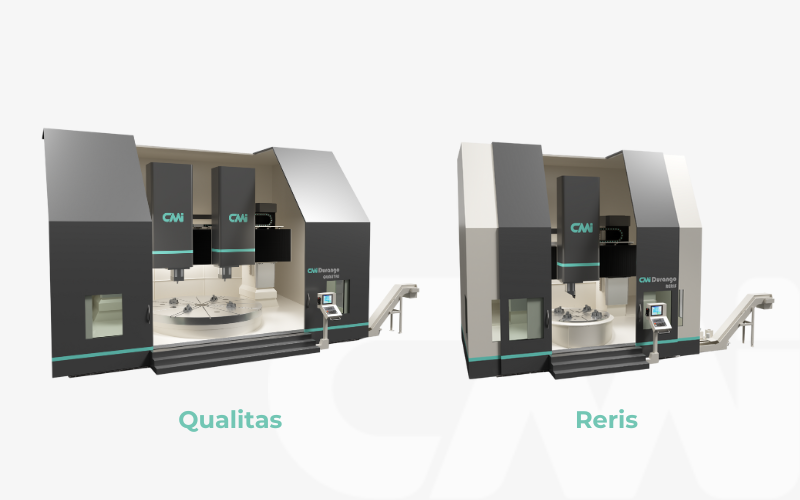

At CMI Durango, we develop two main vertical lathe ranges designed to meet different production environments: RERIS and QUALITAS.

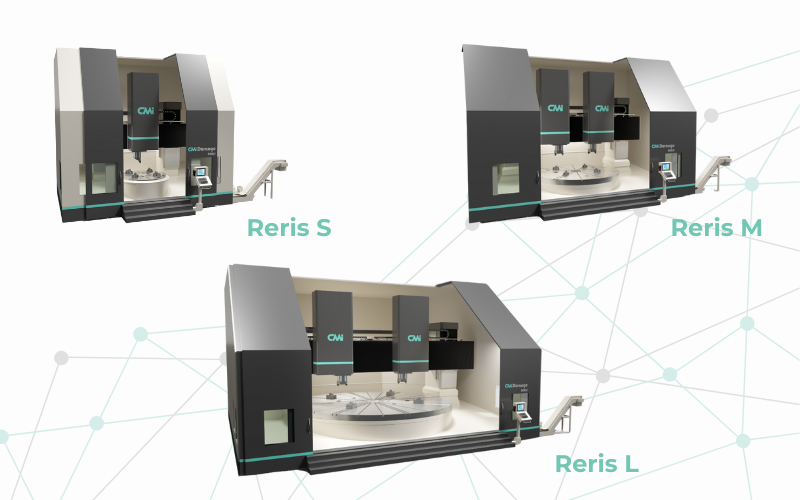

RERIS: stability, power, and precision for heavy-duty machining

The RERIS range is designed for machining large components with maximum precision, reliability, and structural rigidity. It is ideal for environments that require high material removal rates and stable performance during long machining cycles.

- Reinforced structure ensuring rigidity and thermal stability

- High-performance headstock for demanding operations

- Reliable and repeatable performance, even in extended cycles

- Available in three sizes (S, M, and L), adapted to part weight, dimensions, and production requirements

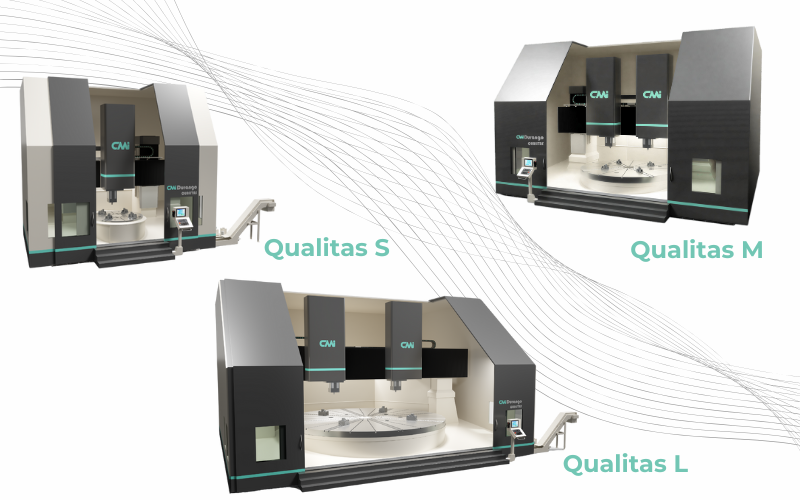

QUALITAS: multiple operations in a single machine

The QUALITAS range consists of multifunction vertical lathes designed to integrate turning, milling, drilling, and tapping operations into a single solution. Ideal for reducing non-productive time and optimizing floor space.

- Turning, milling, drilling, tapping, and grinding in one machine

- Available in three sizes (S, M, and L) to suit different part formats

- Designed to reduce setup times and improve overall productivity

- A versatile solution for plants seeking process efficiency without compromising precision or reliability

RERIS vs. QUALITAS: a quick comparison

| Feature | RERIS | QUALITAS |

| Type of machining | Heavy-duty machining for large, high-demand components | Multifunction machining focused on process and space optimization |

| Operations | Vertical turning | Turning + milling + drilling + tapping + grinding in one machine |

| Available sizes | S, M, and L, with modular options and customized configurations | S, M, and L, adapted to different part formats |

| Automation level | Medium to high, adaptable to process and configuration | High, ideal for integrating complex processes in a single machine |

| Key advantages | Stability, power, and reliability for large components | Versatility, compact design, and reduced non-productive time |

| Recommended sectors | Naval, Aerospace, Energy, Machining workshops, Defense, Capital goods, Railway, Wind, Automotive | Naval, Aerospace, Energy, Machining workshops, Defense, Capital goods, Railway, Wind, Automotive |

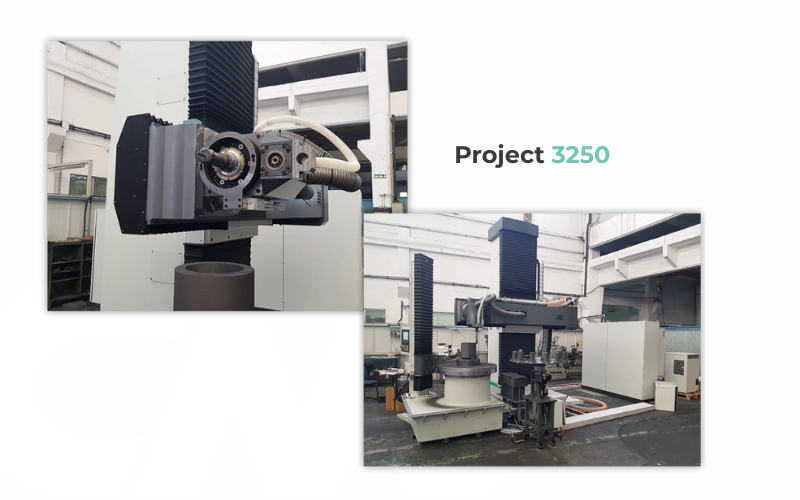

What If you need an even more customized solution?

Beyond our standard ranges, CMI Durango also designs and manufactures fully customized special-purpose machines. Every plant is different, which is why we design each solution based on your specific process, parts, and production objectives.

Can we help you choose the right vertical lathe?

Our team can help you define which type of vertical lathe best fits your application, taking into account all the technical and production-related aspects of your environment.