COMPANY

We are a family-owned machine tool manufacturing company

WHAT WE DO

We develop tailor-made projects based on our accumulated experience and ongoing technological evolution

We adapt to technological advances and to the specific needs of each customer.

We offer a range of products with distinctive characteristics, highly valued and well-established across various sectors, including automotive, railway, aerospace, wind power, energy, defense, machining, shipbuilding, and capital goods.

In addition, we design and manufacture custom machines for projects that require specialized technical solutions. We have in-house capabilities for large-scale machining, allowing us to tackle challenges with agility and precision.

At CMI Durango, we are driven by an innovative spirit that enables us to provide customized solutions.

History

CMI Durango has more than 80 years of experience in the machine tool manufacturing sector.

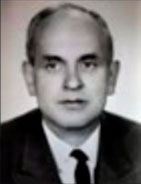

The origins of CMI Durango date back to 1939, when José Estancona, a highly talented and inventive industrial entrepreneur, began manufacturing small machine tools in a modest workshop on Kalebarria Street in Durango.

In the early years, he developed various types of machines, such as boring machines, column drills, horizontal lathes, and broaching machines.

The company relocated to Zeharmendieta Street, No. 2, in Durango (Bizkaia), where CMI Durango is currently located.

The focus on machine tool manufacturing continued, as did an ambitious, though ultimately unsuccessful, attempt to establish an automobile manufacturing plant, first in 1951 in Amorebieta (Bizkaia) and later in 1955 in Pamplona (Navarra).

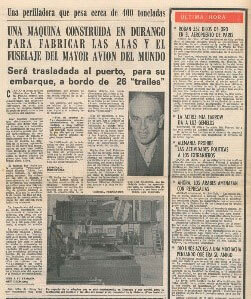

automotive sectors. Among the various projects, one notable example

was the manufacture of a gantry milling machine for machining the wings

of the Boeing 747, the world’s first wide-body commercial aircraft and, at

that time, the longest and heaviest.

DYE established itself as one of the most prominent machine tool manufacturers, with offices in the Americas, Europe, and Asia, and subsidiaries across Spain.

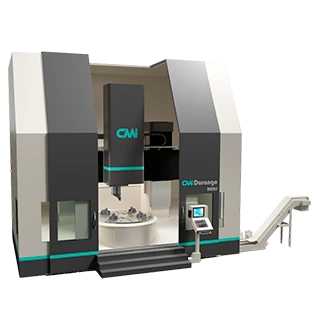

The company developed its first CNC milling machines and vertical lathes, entering a period of expansion and leadership in the international market of large machining centers.

Three- and five-axis gantry milling machines were introduced.

In response to increasing demand for machine tool manufacturing and maintenance, and leveraging over 50 years of expertise in DYE technology and the industry, CMI Aeronáutica relocated to its current facility in the Duranguesado Valley.

The company began operations in Durango with six employees, primarily focused on machine maintenance.

The first gantry milling machine under the “CMI Aeronáutica” brand was designed and manufactured.

The engineering office was expanded, launching custom projects such as milling machines for the railway industry and vertical lathes for the wind power sector, while continuing to enhance the design of three- and five-axis gantry milling machines.

The company changed its trade name to CMI Durango.

Design, manufacture, and commissioning of a multifunction vertical lathe with dual-channel configuration, 10.400mm table diameter, capable of handling parts up to 11.000mm in diameter and up to 100 tons in weight

Rebranding and new commercial strategy.

The product line was standardized while maintaining the company’s approach to tailored machine solutions for specialized projects.

A new commercial approach was consolidated, reinforcing CMI Durango’s position as a manufacturer specialized in custom industrial solutions.

This new phase continues the model based on close customer relationships, technical expertise, and the ability to design and build unique machines for complex manufacturing processes.

The brand identity was also enhanced with a visual image aligned with the company’s essence: innovation, experience, and customization.

Mission and values

Each project brings together advanced technology, manufacturing quality, and customer-focused service

CMI’s mission is to contribute to our clients’ success by collaborating in the pursuit of the best custom solution through the use of new technologies, leveraging our partners, and staying true to our essence, designing and manufacturing robust, versatile, and durable machines, while remaining a benchmark in the application of sustainability principles.

Corporate

mission

Corporate

vision

CMI aims to be a global reference, through its knowledge and technology, in developing sustainable and custom solutions for machining of medium- and large-sized parts, helping build a better present and future from the Basque Country to the world.

People First: Provide the best environment for people to reach their full potential.

Team Excellence: Develop high-quality solutions through teamwork.

Customer Focus: Support the client throughout the entire process.

Constant adaptation: Anticipate and adapt to market changes and the needs of each project.

Integrity: Act with honesty, ethics, and transparency.

Sustainability: Committed to responsible growth.

Corporate

Values

Corporate

mission

CMI’s mission is to contribute to our clients’ success collaborating in the pursuit of the best custom solution through the use of new technologies, leveraging our partners, and staying true to our essence designing and manufacturing robust, versatile, and durable machines while remaining a benchmark in the application of sustainability principles.

Corporate vision

CMI aims to be a global reference, through its knowledge and technology, in developing sustainable and custom solutions for machining of medium and large-sized parts, helping build a better present and future—from the Basque Country to the world.

Corporate

values

People First: Provide the best environment for people to reach their full potential.

Team Excellence: Develop high-quality solutions through teamwork.

Customer Focus: Support the client throughout the entire process.

Constant adaptation: Anticipate and adapt to market changes and the needs of each project.

Integrity: Act with honesty, ethics, and transparency.

Sustainability: Are committed to responsible growth.

Quality

We have a clear objective: to provide a service marked by Precision, Quality, and Customer Care, fully adapted to their needs

Aware of the importance of meeting stakeholder expectations and ensuring the Health and Safety of our personnel, as well as any other individuals present at our facilities, we operate under an integrated Quality, Environmental, and Occupational Health & Safety Management System (QHSE).

We implement a rigorous supplier qualification and evaluation process, selecting only those who meet the required standards to deliver the services or supply the products necessary for each project.

Our quality policy is based on resource optimization, active participation from the entire team, and the continuous pursuit of improvement across all areas of the company.

Furthermore, we apply ECODESIGN, safety, and ergonomic principles throughout our production processes, which allows us to reduce environmental impact from the initial machine design to the end of its lifecycle—while also optimizing operational costs.

Innovation is in the company’s DNA and the facts prove it

1948

As previously introduced, José Estancona, the talented industrial entrepreneur who founded our company

Also built the first Spanish-made car for personal use, at that time, cars were not accessible to most people in Spain. José wanted a vehicle to take his family on trips, but couldn’t acquire one. The solution? Build it himself.

See more

There were no technological advances back then like we have today, so they had to rely on imagination to maximize the limited resources available.

José drew the outline of the car on paper, then projected its silhouette onto a wall, moving it closer or farther from the light source until achieving the right scale.

A passionate mechanic, he managed to overcome every mechanical challenge that arose.

Thanks to his perseverance and enthusiasm, he succeeded in building a car similar to those manufactured by FIAT and well-known in the 1940s.

The DYESA featured a two-stroke, 570cc, water-cooled engine.

Despite being a compact four-seater, the entire Estancona family, seven people in total, fit inside it and were even able to climb the Urkiola mountain pass without any issues.

1951

José made several attempts to register the DYESA, but a series of bureaucratic obstacles delayed the registration until 1951, three years after the vehicle’s construction. The license plate: BI-17271.

The car had been in use from 1948 to 1951 without incident, bearing a plate that read “DURANGO.”

See more

1953

As a true entrepreneur, José faced enormous challenges in sourcing bodywork sheet metal. Eventually, in 1953, he succeeded in building three units of a new model with a design very similar to the British Morris Minor. The car was produced in all three planned versions: two-door, four-door, and van.

See more

The new vehicles featured a three-cylinder version of the previous engine, with 800cc and approximately 22 horsepower.

These vehicles were branded ESTANCONA.

A crucial aspect of this development was that the manufacturer was a mechanical engineering company, providing strong technical and industrial support for the project.

José outlined ambitious production plans: 2,000 units annually during the initial phase, then 4,000, ultimately targeting 10,000 units. The goal was to sell them at 20,000 pesetas each.

Nothing could stop him. José Estancona even presented the ESTANCONA prototype in Madrid to the Head of State, who responded positively and granted the project “national interest” status.

and 1957

Nevertheless, as an industrial entrepreneur, José Estancona did not surrender. He redirected his efforts fully into DYE technology and the manufacturing of machine tools.