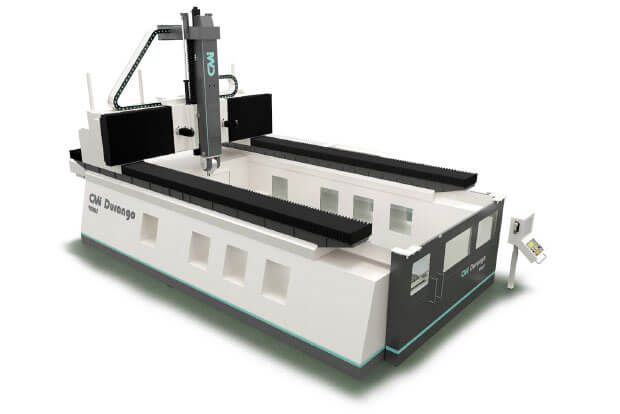

VERUS Milling machine

Composite Gantry model

High speed, high performance Gantry milling machine. It mechanises large parts of different morphology, combining a high capacity of chip removal and an excellent high quality finish.

Depending on their configuration, their applications are diverse and are aimed at the automotive, aeronautics and capital goods sectors.

Applications:

5-Axis VERUS Milling machine

Technical characteristics

| Longitudinal Path (X) | 5.000 ÷ 20.000 | ||

| Transversal Path (Y) | 2.500 ÷ 5.000 | ||

| Vertical Path (Z) | 1.000 ÷ 1.750 | ||

| Distance between columns (mm) | 3.450 ÷ 5.950 | ||

| Max. distance between spindle and table (mm) | 1.200 ÷ 1.950 | ||

| Maximum feed rate X-Axis (m/min) | 40 | ||

| Maximum feed rate Y-Axis (m/min) | 40 | ||

| Maximum feed rate Z-Axis (m/min | 24 | ||

| Maximum table weight – (kg/m²) | 15.000 | ||

| Drives on X-Axis | 4 rack and pinion motors (2+2) | ||

| Drives on Y-Axis | 2 rack and pinion motors | ||

| Drives on Z-Axis | Ball screw spindles | ||

| Precision according to ISO 8636-1:2000 | |||

headstock

| A-Axis | C-Axis | |

| Nominal / Maximum torque (Nm) | 840 / 1.340 | 1.020 / 1.960 |

| Rotation speed (º/s) | 360 | 360 |

| Locking torque(Nm) | 4.000 | 4.000 |

| Rotation angle (º) | ± 110 | ± 360 |

| Measurement system | Absolute | Absolute |

| Positioning precision (“) | ± 5 | ± 2 |

| Approx. total weight (kg) | 950 | 950 |

Spindles

| CS60-180-S | CS42-180-S | |

| PowerS1 / S6 (kW) | 60 / 80 | 42 / 53 |

| Nominal speed (r.p.m.) | 7.000 | 2.000 |

| Par S1 / S6 (Nm) | 82/ 106 | 201 / 253 |

| Max. speed (r.p.m.) | 22.000 | 10.000 |

| Cone housing | HSK – A63 | HSK – A100 |

| Design |  |

|

CNC

Siemens 840D

Heidenhain ITNC 640

Fanuc 31i – B5

Fagor 8065

Accessories

Standard

Optional

| Tool regulator | |

| Perimeter fencing | |

| 60 tool changer | |

| Chip extractor | |

| Internal cooling | |

| 30 / 40 / 100 tool changer |

| Cooling equipment | |

| Laser tool | |

| Probe tool | |

| 2 work areas | |

| Full enclosure |